Secrets of The World Class Warehouse Assessment

- May 2, 2021

- 10 min read

Updated: Oct 10, 2022

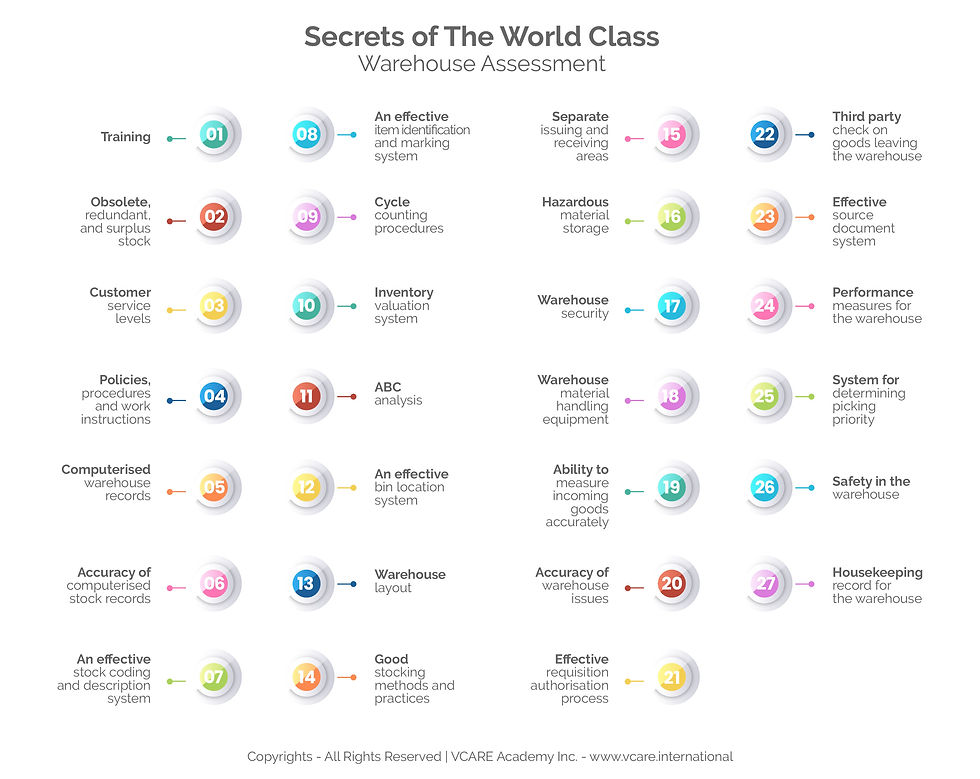

Let us examine a few of the aspect that a warehouse assessment might look at in a typical store or warehouse. These are not listed in any order of importance. The importance of each of these aspects would depend on the type of store being assessed and the type of business that they serve.

Training

Obsolete, redundant, and surplus stock

Customer service levels

Policies, procedures and work instructions

Computerised warehouse records

Accuracy of computerised stock records

An effective stock coding and description system

An effective item identification and marking system

Cycle counting procedures

Inventory valuation system

ABC analysis

An effective bin location system

Warehouse layout

Good stocking methods and practices

Separate issuing and receiving areas

Hazardous material storage

Warehouse security

Warehouse material handling equipment

Ability to measure incoming goods accurately

Accuracy of warehouse issues

Effective requisition authorisation process

Third party check on goods leaving the warehouse

Effective source document system

Performance measures for the warehouse

System for determining picking priority

Safety in the warehouse

Housekeeping record for the warehouse

01 - Training

This is probably the universal problem in most stores that I measure, the lack of education and training of the personnel working in the warehouse. It is amazing to me that we give responsibility for the safe custody of Millions of Dollars of one of our most valuable assets to "not yet competent" employees. Then we wonder why it goes missing!

All employees in the warehouse and those who interact with the warehouses, such as buyers and production supervisors, need to attend a CSSC, Certified Stores and Stock Controller program, together with their Manager. This ensures that everybody is aware of how the stores and warehouse should operate and what they can do to improve the stores and warehouse operations.

02 - Obsolete, Redundant, and Surplus Stock

Most of us hate throwing things away, and consequently our warehouse become cluttered with obsolete, redundant and surplus stock. We use valuable assets to look after these stocks, assets that could be used to better effect elsewhere.

If you have stock that is not needed "just now", then why do we have it, dispose of it and make space for stock that is required.

The decision to dispose of unwanted stock is not normally the responsibility of the warehouse team, but it should be their responsibility to highlight items that are ‘gathering dust and hence cost’ in their store and continue to badger Management until the decision is made to dispose of the stock.

03 - Customer Service Levels

Many times, I find that the stores, both internal and external, customer service is not measured. The store is there to support the manufacturing process or the sales and marketing objectives, measure its ability to do this effectively. The stores should consult with their customers to ascertain where their service is lacking and put programs in place to rectify the situation.

04 - Policies, Procedures and Work Instructions

If the stores are to operate in a world class manner it is important that the operating procedures are documented properly. This documentation is lacking in many warehouses that I visit.

Firstly, management needs to put forward a policy as to how the stores and warehouses should operate. To ensure that this policy is carried out, the warehouse team need to create procedures that will support the policy, and to ensure that they work using best practices. In some cases, it could be necessary to write work instructions to make sure that stores personnel use and enter information into the computer system in the correct way to ensure accurate and real time inventory records.

05 - Computerised Warehouse Records

Today it is essential that all warehouse records are computerised. A company without computerised inventory records is not going to be able to compete in the long term. It is not often that one finds stores that are not computerised, but it does happen.

Sometimes sundry stores or engineering stores are not computerised, and controls are very lax with ‘shrinkage’ being a major problem. This is particularly evident in some stationary stores just before the schools start a new school year! I hate to think how many poorly controlled engineering stores provide parts for weekend plumbing and electrical projects at employees’ homes!

When it comes to computerisation, it is important that all transactions that update the on-hand balances in the store are performed by the warehouse team, as soon as possible after the physical transaction has taken place. If other personnel outside the store perform computer transactions that update the store records, we will never be able to hold the warehouse team responsible for accuracy in their stores and warehouse.

06 - Accuracy of Computerised Stock Records

Almost without exception when I ask people that work in the store what the level of accuracy is of their inventory records, I get responses such as "not bad" or "OK". Very rarely can they give me an exact figure, as this important aspect of storekeeping is not measured or communicated to the staff.

This is the key measure in a store and should be known to everybody that works in, or interacts with, the store. It should be visibly displayed and discussed, and its improvement worked upon relentlessly until near perfection is obtained.

07 - An Effective Stock Coding and Description System

This aspect is not normally the responsibility of the warehouse team, but with an effective system in place, it makes the storekeeping function less difficult.

Problems I find in this area are such things as ‘horrifically’ long alpha numeric item numbering systems that are liable to input errors. In addition, the description fields are not constructed properly to allow efficient and accurate searches to take place.

08 - An Effective Item Identification and Marking System

It is important that every item in warehouse is marked with the company’s item number. Without this positive identification, mistakes can easily be made when picking, counting, binning, etc. We must never rely on our warehouse team’s memories or experience to recognise what they are looking for. One day they will not be there and then how will we find that item?

I always say that a test of a well-run warehouse, is to give me a pick list and I should be able to find, identify and pick an order just as fast as any of the persons working in the warehouse. Would your warehouse pass this test?

09 - Cycle Counting Procedures

Many of the warehouses that I visit have attempted to set up cycle counting procedures, but many of them focus on just correcting the on-hand balances and not investigating the reasons why the stock records became inaccurate in the first place. Without this focus on the reasons for stock inaccuracy, the stock will never improve in its accuracy. Stock accuracy must be a by-product of the cycle counting process.

This subject is addressed during the specific stock record accuracy training for the warehouse team.

10 - Inventory Valuation System

I believe it is important that the persons working in the warehouse have a good idea of the value of the stock that is under their care. If they understand the value, they are more likely to look after it with the respect it deserves.

11 - ABC Analysis

ABC analysis is probably one of the oldest inventory management techniques, but in my view, is still one of the most useful. The stock in the warehouse needs to be categorised into its ‘ABC’ categories by ‘Dollar Usage’ value.

The main use for ‘ABC’ analysis in the warehouses is in the cycle counting procedures, where typically we would try and set up a program that counts ‘A’ items once a month, ‘B’ items, once every three months and ‘C’ items twice a year.

This ‘ABC’ analysis would also be used in other areas of the business such as forecasting, purchasing, materials planning, etc.

12 - An Effective Bin Location System

If the warehouse does not have an effective bin location system, customer service can suffer. It is important that stock can be located accurately and quickly and that we do not rely on the warehouse team to remember where parts are stored.

13 - Warehouse Layout

A good warehouse layout goes together with good housekeeping and good location control. A warehouse must be designed to suit the type of racking or storage systems used as well as the materials handling equipment required to pick and put items away.

It is important that the warehouse is designed to allow for the maximum space utilisation. In many cases I find warehouses have just happened rather than any design being put into them. A corner is fenced off in the factory and that is then called the warehouse. No thought is put into how the warehouse will operate efficiently and the material flow through the warehouse.

14 - Good Stocking Methods and Practices

Under this heading I look to see if the storage equipment suites the type of goods being stored. In addition, is fast and slow moving stock stored in the correct areas to assist efficient picking? And are items stored in such a way such as they will not be damaged or suffer deterioration. For stock with a shelf life, is it rotated FIFO?

15 - Separate Issuing and Receiving Areas

It is important for security and for accuracy that the receiving and issuing areas of the warehouse are separate. When they are next door to each other, or worse still, use the same space, mistakes can easily happen. Suppliers delivering can ‘accidentally’ load up items for shipping and vice versa when our attention is distracted elsewhere.

16 - Hazardous Material Storage

If hazardous materials form part of the stock holding, it is important that these are stored in a separate hazardous material section, away from the main warehouse. This warehouse should be in a position such that it can be easily viewed in case problems do occur and can be spotted quickly and action taken timeously.

17 - Warehouse Security

This is probably the number one problem that I find in the warehouses that I visit. Generally, there is no security and employees are allowed to wander around the warehouse unaccompanied and help themselves to whatever they require.

Your stock will never ever become accurate if a situation such as this is allowed to continue. Treat your warehouse as a bank. When was the last time you gained access to the vault in your local bank? These high street bank vaults generally hold less monetary value that most raw material or finished goods warehouses in manufacturing.

I believe that an employee being found in the warehouse, without the permission of the warehouse team, is just as much a serious offence as smoking in a dynamite factory. A serious warning or instant dismissal should be the order of the day, this should also include the boss!

18 - Warehouse Material Handling Equipment

As warehouse are not a productive area, they generally fall to the back of the queue when requesting decent and appropriate materials handling equipment. For the warehouse team to carry out their task efficiently and effectively they need the right equipment to unload, put away, pick and ship/issue the items under their control. Without the correct equipment this can affect both internal and external customer service.

19 - Ability to Measure Incoming Goods Accurately

This has been shown to be a major cause of inaccurate warehouse records. I have uncovered so many instances where suppliers have apparently deliberately under supplied because they know the customer does not have the correct equipment to measure the incoming goods.

The rule here is don’t believe the supplier when he says there are 300 items in box or 200 metres on a roll, find ways to check the incoming material. If you cannot measure incoming inventory, it is likely that stock accuracy will be seriously compromised. The banks do not believe you when you say there are so many coins in a bag or notes in a bundle and to overcome manual counting, which is also inaccurate, they have developed special machines to perform the task accurately.

20 - Accuracy of Warehouse Issues

People make mistakes, and if they say they do not, then they don’t do anything. There is nothing more frustrating than collecting your goods from the warehouses and finding there are mistakes when you get back to the workplace. This should be a performance measure that is tracked in the warehouse and actions put in place to improve this aspect of warehousing.

21 - Effective Requisition Authorisation Process

A requisition can be likened to a cheque in the banking system, treat it as such. Have a good authorisation process in place. Just like the bank, the warehouse team should have a copy of the signatures of the authorised person that can draw different categories of stock from the warehouse. Without this, the warehouse team cannot be held accountable for items that are issued to unauthorised persons.

22 - Third Party Check on Goods Leaving the Warehouse

This aspect falls in line with accuracy of warehouse issue. Without a check being made of picked items prior to issue out of the warehouse, it is dead easy to illegally get product out of the warehouse if the warehouse team is in cahoots with the person requisitioning the material. This is an easy and favourite method of stealing from the warehouses.

23 - Effective source document system

It is important that source documents for all warehouse’s transactions are filed in the warehouse. These are invaluable when cycle counting programs are in place as we need to determine how and why stock has become inaccurate.

These source documents should cover receipts into the warehouse, movement of stock within the warehouse, and issue of materials from the warehouse.

24 - Performance Measures for the Warehouse

The prime measure for the warehouse is normally stock accuracy and I believe the job description for a warehouse team should only be one line: "To attain and maintain a 100% accurate, real time store".

Other measures should revolve around customer service, accuracy of issues, speed of issues, and accuracy of receipts.

25 - System for Determining Picking Priority

In small warehouses, picking priorities are not normally an issue, but where a store or warehouse is large and many orders are picked daily by many warehouse teams, a priority system needs to be put into place.

All orders, and picking assignments, are not necessarily equal, there are urgent orders, priority customers and it’s not much good picking an order that has to go by ship, after the ship has sailed. This picking priority system needs to be designed to suit the company and policy from top management.

26 - Safety in the Warehouse

I have very rarely come across people being hurt whilst working in the warehouse, but there is potential for this to happen, and all procedures need to consider the safety aspects of working in a particular warehouse. Some of the basic issues could include, should warehouse team wear hard hats and safety boots, and are there convex mirrors situated at the ends of aisles to enable forklift drivers to see hazards around the corner.

27 - Housekeeping Record for the Warehouse

Finally, I have never seen a messy warehouse that is accurate. Therefore, I believe housekeeping is of paramount importance. It is almost possible to guestimate the stock accuracy in a warehouse by judging how tidy it is. One can almost see the pride on the part of the warehouse teams in a tidy warehouse, and if they take a pride in everything being away in its place, they often take a pride in the accuracy of their transactions.

I hope that I have been able to give you a few practical suggestions on how to gain 100% real time records in your store or warehouse. Start by assessing the stores operation to determine the base line for any improvement project and as a comparison to a world class operation. Educate all your warehouse teams in the CSSC, Certified Stores and Stock Controller as well as cycle counting principals. Set up a project to implement continuous improvement in your warehouse. Finally, assess the warehouse again at the end of the project to identify further improvement required on you quest for world class status.

Presented By

Ken Titmuss

CFPIM, CSCP, SCOR-P, CPF, CS&OP, PLS, CDDP, CSCA, CDDL, CLTD, DDPP, DDLP, AEF, CSSC, CPIA Chief Executive Officer at Kent Outsourcing Services

A successful career in supply chain necessitates a never-ending thirst for knowledge and the most up-to-date supply chain skills and knowledge. Even though continuing education and certification programs can take time and money, they help get your specialized knowledge or skills recognized.

When professionals have training that other professionals lack, it distinguishes them and sets them apart from the crowd. Certification and master classes show that the professionals are committed to learning, excelling, and using best practices.

Featured Certification Programs

Certified Stores and Stock Controller (CSSC)

Certified Production and Inventory Analyst (CPIA)

Featured Mini-Master Classes

Supply Chain Framework and Strategy

Collaboration among Sustainability, Procurement and Supply Chain

Implementing 3PL and 4PL Strategies in the Value Chain

Supply Chain Sustainability with Circularity to Drive Profitability

Comments