Why and What Should You Forecast?

- VCARE Academy

- May 17, 2021

- 3 min read

Updated: Oct 10, 2022

Generating a statistical forecast, by whatever means, is not the same as creating a demand plan in your business, it is only the first part of a four-part process.

Over the 30 years I have visited and worked with about 300 companies. One of the first questions asked is often “What is your budget for Demand Management in the business?” The response is often surprise as to the need for one and comments like, the salesmen are responsible for forecasts and they ‘suck-their-thumbs’ for half an hour at the end of the month, where is the need for a budget? It is amazing how many companies run their whole business based on a salesman’s thumb suck!

Demand management and coming up with a reasonable demand plan, is a key process in any business. If you don’t have a reasonable idea of all the demands on your business into the future, how on earth are you going to be able to plan the supply of resources in the form of materials, capacity and labour?

A business requires the best forecast it can for various reasons, including:

To guide marketing on the business required to keep the company profitable.

To enable the company to plan production properly.

To be able to buy long lead-time raw materials and components.

To be able to productively schedule the work force.

To be able to prepare a business plan for future investment purposes.

Most businesses are still using judgmental or intuitive forecasting techniques where as they should be using more scientific methods. Forecasts can also get mixed up with goal setting and become the yardstick by which salesmen are measured. Hence, the reluctance of the salesmen to be involved in the process as, due to the first rule of forecasting, they will always be wrong. The advantage of putting a consensus demand management process in place is that it separates the forecasting process from goal setting. Forecasting than becomes systemic and objective.

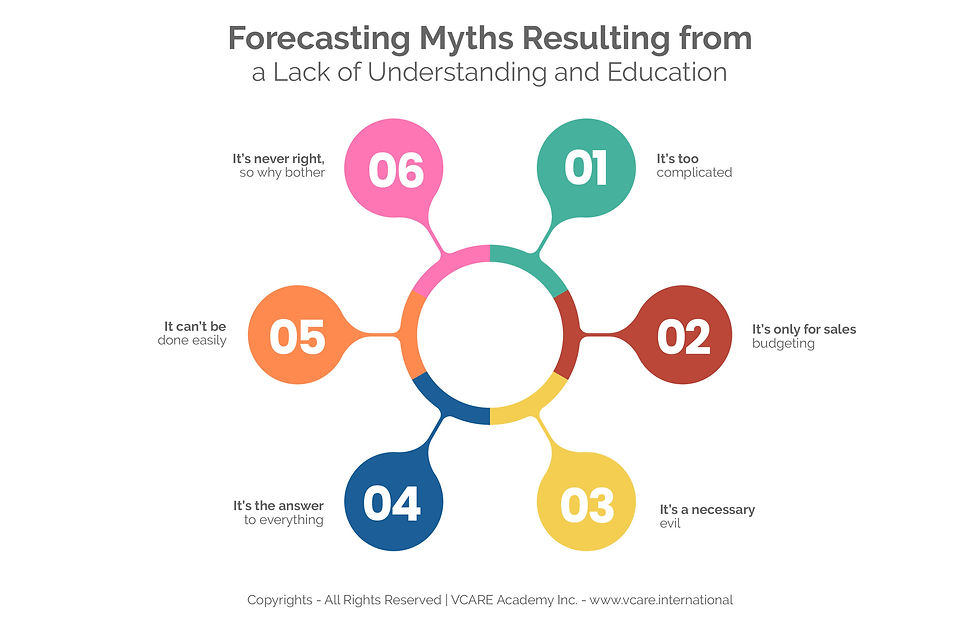

Some of the common forecasting myths, mainly resulting from a lack of understanding and education, are:

It’s too complicated

It’s only for sales budgeting

It’s a necessary evil.

It’s the answer to everything

It can’t be done easily

It’s never right, so why bother.

Some of the common gripes one comes across, mainly from the sales team, are:

You can’t forecast this business

Forecasting is not in my job description

It’s impossible to make any sense out of this forecasting stuff

If we could get an accurate forecast it would solve all our problems

We need more detail in the forecast

Forecasting is a waste of time around here, nobody takes any notice of them

We know the forecast is going to be wrong, so why bother

We start a lot of stuff around here, but we don’t finish much

And in operations, we are the victims of a lousy forecast and there is nothing we can do about it.

Presented By

Ken Titmuss

CFPIM, CSCP, SCOR-P, CPF, CS&OP, PLS, CDDP, CSCA, CDDL, CLTD, DDPP, DDLP, AEF, CSSC, CPIA Chief Executive Officer at Kent Outsourcing Services

A successful career in supply chain necessitates a never-ending thirst for knowledge and the most up-to-date supply chain skills and knowledge. Even though continuing education and certification programs can take time and money, they help get your specialized knowledge or skills recognized.

When professionals have training that other professionals lack, it distinguishes them and sets them apart from the crowd. Certification and master classes show that the professionals are committed to learning, excelling, and using best practices.

Featured Certification Programs

Certified Stores and Stock Controller (CSSC)

Certified Production and Inventory Analyst (CPIA)

Featured Mini-Master Classes

Supply Chain Framework and Strategy

Collaboration among Sustainability, Procurement and Supply Chain

Implementing 3PL and 4PL Strategies in the Value Chain

Supply Chain Sustainability with Circularity to Drive Profitability

Comments